Advantages of laser cutting machine for stainless steel

In recent years, with the development of laser technology, application of laser technology in the field of cutting is more and more mature, at the same time, the rapid growth of the stainless steel pipe demand in our country, the cutting efficiency and tubing incision requirements also more and more high, laser cutting machine, to pipe brought a qualitative leap in processing, laser cutting machine for cutting stainless steel pipe have what advantage?

1. The laser pipe cutter can guarantee the precision of cutting

Compared with the traditional machining equipment such as flame cutting, linear cutting, plasma cutting and water cutting, the precision of laser pipe cutting machine can be controlled by the program to achieve the cutting effect which other cutting techniques cannot reach. At present, the precision of traditional cutting equipment is around 0.05mm, while the precision of laser pipe cutting machine will be higher!

2. The laser pipe cutter has strong flexibility

Why is the laser pipe cutter very flexible?

First of all, the Angle cutting problem can be well solved. Our traditional pipe cutting machine can only cut 45 to 90 degrees of Angle, which is a little small and a little large. We have also encountered many customers who have encountered such troubles. There is no restriction on laser cutting, no matter what the Angle of cutting requirements, can pass a good competent. That is to say, you can cut as much as you want! This is good news for the door and window industry. In the future, laser cutting opportunities will have a place in the door and window cutting field! Laser pipe cutter

Secondly, its flexibility is also reflected in the shape cutting and drilling, only through simple programming, to be able to work out the desired shape;

Finally, the flexibility of the laser pipe cutter is also shown in reducing the number of molds used.

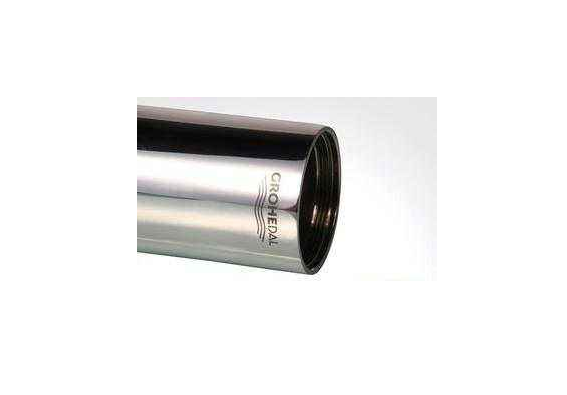

3. The laser pipe cutting machine can guarantee the quality of cutting pipe mouth

The appearance of laser pipe cutting machine also brings a certain impact to many industries, such as traditional pipe cutting machine industry, chamfering machine industry, punching machine industry, punching machine industry and so on. These shock not only reflected in the perspective of what is said above, shape cutting, punching, cutting, etc., also reflected in the cutting nozzle is very good, no burr, no dust, changeless form, do not need to undertake secondary processing, there are a lot of original through traditional pipe cutter for cutting the need deburring or chamfering, after in the future, only need a laser cutting machine, can solve the series of problems.

1. The laser pipe cutter can guarantee the precision of cutting

Compared with the traditional machining equipment such as flame cutting, linear cutting, plasma cutting and water cutting, the precision of laser pipe cutting machine can be controlled by the program to achieve the cutting effect which other cutting techniques cannot reach. At present, the precision of traditional cutting equipment is around 0.05mm, while the precision of laser pipe cutting machine will be higher!

2. The laser pipe cutter has strong flexibility

Why is the laser pipe cutter very flexible?

First of all, the Angle cutting problem can be well solved. Our traditional pipe cutting machine can only cut 45 to 90 degrees of Angle, which is a little small and a little large. We have also encountered many customers who have encountered such troubles. There is no restriction on laser cutting, no matter what the Angle of cutting requirements, can pass a good competent. That is to say, you can cut as much as you want! This is good news for the door and window industry. In the future, laser cutting opportunities will have a place in the door and window cutting field! Laser pipe cutter

Secondly, its flexibility is also reflected in the shape cutting and drilling, only through simple programming, to be able to work out the desired shape;

Finally, the flexibility of the laser pipe cutter is also shown in reducing the number of molds used.

3. The laser pipe cutting machine can guarantee the quality of cutting pipe mouth

The appearance of laser pipe cutting machine also brings a certain impact to many industries, such as traditional pipe cutting machine industry, chamfering machine industry, punching machine industry, punching machine industry and so on. These shock not only reflected in the perspective of what is said above, shape cutting, punching, cutting, etc., also reflected in the cutting nozzle is very good, no burr, no dust, changeless form, do not need to undertake secondary processing, there are a lot of original through traditional pipe cutter for cutting the need deburring or chamfering, after in the future, only need a laser cutting machine, can solve the series of problems.

评论

发表评论